air cleaner

air cleaner

first post!

hi,

im having a bit of trouble with my air cleaner; two of the three bolts have fallen out, and the bottom nut has fallen off the last, so ive had to fix it on to the carburettor with zip ties and bungee cord!

even if i find replacement bolts, at least one of teh bottom nuts would be very hard to put back again;- and i cant work out what was holding the bolts in when they were there anyway. -whats to stop the bolts falling out again before the top nuts are screwed in?

obviously, its worked for 20 years, so i must be missing something, but i cant figure out what!

thanks,

gareth

hi,

im having a bit of trouble with my air cleaner; two of the three bolts have fallen out, and the bottom nut has fallen off the last, so ive had to fix it on to the carburettor with zip ties and bungee cord!

even if i find replacement bolts, at least one of teh bottom nuts would be very hard to put back again;- and i cant work out what was holding the bolts in when they were there anyway. -whats to stop the bolts falling out again before the top nuts are screwed in?

obviously, its worked for 20 years, so i must be missing something, but i cant figure out what!

thanks,

gareth

Hi Gareth,

I assume your car has the B14 engine (1397cc) as the problem you describe is most common (very common indeed) with the Weber 32DIR carburettor.

This problem has actually been well documented before in various threads (indeed recently). As you have only just joined (welcome by the way) I will briefly go through it for you.

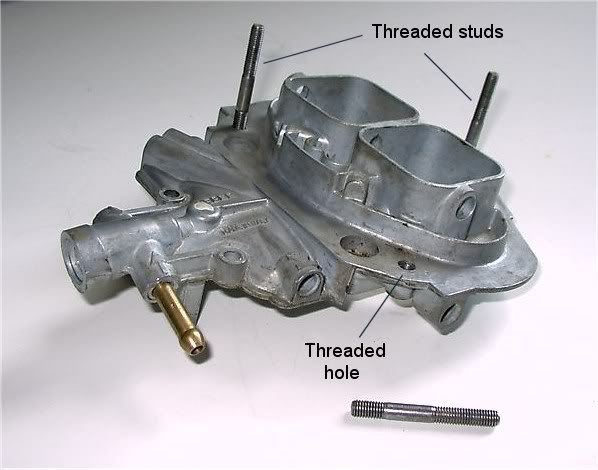

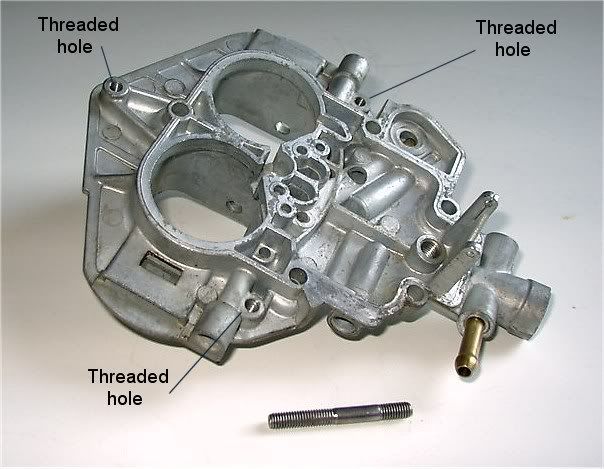

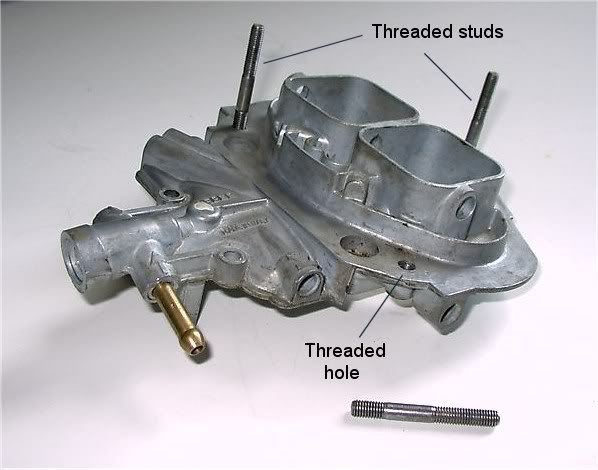

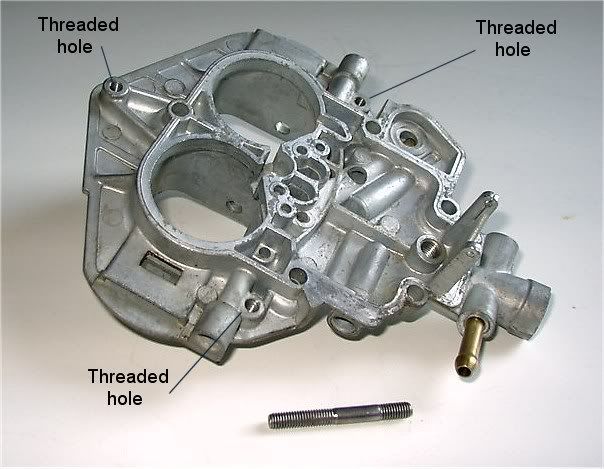

The air cleaner should not be retained by nuts and bolts - there should be 3 threaded studs fitted to the carb top. (the thread is M5 x 0.80 (8mm AF nuts).

Overtightening over the life of the car results in these threaded studs pulling out. The common fix is to replace them with nuts and bolts.

The correct fix is to 'helicoil' the carb top, or re-tap the holes 'next size up' and use stepped studs, or use larger studs/nuts.

If you are not 'diy' inclined it would be an easy task for a garage or small engineering firm to fix. (should be perfectly possible to repair with the carb still on the car). If you go the larger stud route you will need to drill out the washers under the nuts in the air cleaner, and possibly enlarge the holes in the air cleaner housing.

Hope this helps - Mac.

I assume your car has the B14 engine (1397cc) as the problem you describe is most common (very common indeed) with the Weber 32DIR carburettor.

This problem has actually been well documented before in various threads (indeed recently). As you have only just joined (welcome by the way) I will briefly go through it for you.

The air cleaner should not be retained by nuts and bolts - there should be 3 threaded studs fitted to the carb top. (the thread is M5 x 0.80 (8mm AF nuts).

Overtightening over the life of the car results in these threaded studs pulling out. The common fix is to replace them with nuts and bolts.

The correct fix is to 'helicoil' the carb top, or re-tap the holes 'next size up' and use stepped studs, or use larger studs/nuts.

If you are not 'diy' inclined it would be an easy task for a garage or small engineering firm to fix. (should be perfectly possible to repair with the carb still on the car). If you go the larger stud route you will need to drill out the washers under the nuts in the air cleaner, and possibly enlarge the holes in the air cleaner housing.

Hope this helps - Mac.

hi there!

couldnt have said it better Mac. I did this job last week on a friends 340.

I went for the nuts and bolts route. I was going to publish it here but it was a 100% perfect job so I left it.

I re-tapped the M5 holes to M6X1.0 and used M6 bolts with a 10mm head. This isnt perfect as for the hole above the solenoid idle valve and the opposite side ( holes shown by X below)

Carb seen from top

X

O

X

the top of the bolt doesnt reach the base of the carb - need smaller bolt heads eg 8mm maybe? I used 10mm locking nuts. The holes in the air filter do need to be enlarged for M6 bolts - the hole is a snug fit for a M5.

Ideally, I'd like to have used 8mm locknuts but could find M6 X1.0 8mm locknuts

Ideally, at some point I'd like to swap the bolts I used for longer one with also smaller heads.

I also used loctite on the thread of the bolts to hold them in, locking nuts to hold the air filter on and locktite there also.

For this route you need to bolt from the underneath of the carb upwards. A further problem with the 10mm heads is they catch on the side of the carb half way up. So... I had to remove the top of the carb ( 5 screws from memory) - the section shown in Mac's top picture and screw the bolts in here first, then bolt this back onto the carb. A far overly complex job - only coz it was a rush job as they guy wanted his car and I had to make do with B&Q parts!!!

Mac - what was volvos repair? M6 studs? Where could you get those now?

PS are those pics you own or ones volvo used? very clear!!!

all the best and goodluck!!

Shimon

couldnt have said it better Mac. I did this job last week on a friends 340.

I went for the nuts and bolts route. I was going to publish it here but it was a 100% perfect job so I left it.

I re-tapped the M5 holes to M6X1.0 and used M6 bolts with a 10mm head. This isnt perfect as for the hole above the solenoid idle valve and the opposite side ( holes shown by X below)

Carb seen from top

X

O

X

the top of the bolt doesnt reach the base of the carb - need smaller bolt heads eg 8mm maybe? I used 10mm locking nuts. The holes in the air filter do need to be enlarged for M6 bolts - the hole is a snug fit for a M5.

Ideally, I'd like to have used 8mm locknuts but could find M6 X1.0 8mm locknuts

Ideally, at some point I'd like to swap the bolts I used for longer one with also smaller heads.

I also used loctite on the thread of the bolts to hold them in, locking nuts to hold the air filter on and locktite there also.

For this route you need to bolt from the underneath of the carb upwards. A further problem with the 10mm heads is they catch on the side of the carb half way up. So... I had to remove the top of the carb ( 5 screws from memory) - the section shown in Mac's top picture and screw the bolts in here first, then bolt this back onto the carb. A far overly complex job - only coz it was a rush job as they guy wanted his car and I had to make do with B&Q parts!!!

Mac - what was volvos repair? M6 studs? Where could you get those now?

PS are those pics you own or ones volvo used? very clear!!!

all the best and goodluck!!

Shimon

Enjoy your 300s

Hi Shimon,

Volvos repair would be a new carb top! (bearing in mind most of the vehicles that we dealt with at the tech centre were only up to 5-6 years old at most).

The problem is more of a 'middle age' thing and as a non warranty repair I guess 'helicoiling' or stepped studs would be favoured.

Quite where you can get stepped M5/M6 studs from - who knows - time to drag out the 'Myford' and make some I guess!

The pics ? - mine, all mine I tell you, he, he, he. (seriously I still have a fair store of obscure bits lying around (ask Vart) so can usually come up with something tp snap for my little stories).

Mac.

Volvos repair would be a new carb top! (bearing in mind most of the vehicles that we dealt with at the tech centre were only up to 5-6 years old at most).

The problem is more of a 'middle age' thing and as a non warranty repair I guess 'helicoiling' or stepped studs would be favoured.

Quite where you can get stepped M5/M6 studs from - who knows - time to drag out the 'Myford' and make some I guess!

The pics ? - mine, all mine I tell you, he, he, he. (seriously I still have a fair store of obscure bits lying around (ask Vart) so can usually come up with something tp snap for my little stories).

Mac.

mac,

thank you sir, you are a legend!

it all makes sense now, cheers.

it is actually the studs that i have, though only only of them is remaining.

-do you know where i could get some new ones cheap? i tried B&Q, but no luck. i think i will try the helicoiling option, seems easiest. -i assume i need locking nuts on the top?

thanks, gareth

p.s. im sure ill be back with more questions later, this website is great!

(and theres lots to fix on me old 340!)

thank you sir, you are a legend!

it all makes sense now, cheers.

it is actually the studs that i have, though only only of them is remaining.

-do you know where i could get some new ones cheap? i tried B&Q, but no luck. i think i will try the helicoiling option, seems easiest. -i assume i need locking nuts on the top?

thanks, gareth

p.s. im sure ill be back with more questions later, this website is great!

(and theres lots to fix on me old 340!)

Hi again Gareth,

Be warned this site is addictive!

Studs - Volvo part no.is 3287035, I don't think you can get them anymore but it's worth asking at the main stealers. Failing that a Weber dealer should be able to supply (Burlen Fuel Systems do Weber now I believe).

They are actually quite easy to make out of 5mm steel rod - if you have the gear. The studs are no problem.

As for 'helicoiling' - try a good independant garage or a small engineering firm (you can actually buy a Helicoil kit with 10x5mm inserts for about £25.00 so it shouldn't cost too much.

Yes - use 'nylocs' on the top of the studs (very cheap n' easy to find).

If you really get stuck for studs & nut let me know - I'm sure I can find some up for you. (but I really don't think you will have any bother finding some). Whoever you get to do the re-threading should be able to supply.

Be warned this site is addictive!

Studs - Volvo part no.is 3287035, I don't think you can get them anymore but it's worth asking at the main stealers. Failing that a Weber dealer should be able to supply (Burlen Fuel Systems do Weber now I believe).

They are actually quite easy to make out of 5mm steel rod - if you have the gear. The studs are no problem.

As for 'helicoiling' - try a good independant garage or a small engineering firm (you can actually buy a Helicoil kit with 10x5mm inserts for about £25.00 so it shouldn't cost too much.

Yes - use 'nylocs' on the top of the studs (very cheap n' easy to find).

If you really get stuck for studs & nut let me know - I'm sure I can find some up for you. (but I really don't think you will have any bother finding some). Whoever you get to do the re-threading should be able to supply.

Hi MJ,

A 'helicoil' is actually a new thread of the correct size fitted into a stripped hole or bore.

The damaged hole is drilled and tapped to a size specific to the insert being fitted and a steel thread in the form of a coil (like a coil spring) is wound in using a special insertion tool (which engages in a 'tag' on the end of the coil - this tag breaks off leaving the new thread in place).)

The technique is commonly used in aluminium components, not only to restore damaged threads, but also to fit steel threads to take higher loadings (as long as the insert doesn't pull out),

Mac.

A 'helicoil' is actually a new thread of the correct size fitted into a stripped hole or bore.

The damaged hole is drilled and tapped to a size specific to the insert being fitted and a steel thread in the form of a coil (like a coil spring) is wound in using a special insertion tool (which engages in a 'tag' on the end of the coil - this tag breaks off leaving the new thread in place).)

The technique is commonly used in aluminium components, not only to restore damaged threads, but also to fit steel threads to take higher loadings (as long as the insert doesn't pull out),

Mac.

Shimon,

If you are still playing with that one, the way I found easiest was to drill out the carb top 5.5mm, and the air filter 6mm, and re tap the carb top, then use normal bolts. If I knew at the time, I think I would have made up some studs though.

B&Q sell 6mm threaded rod by the metre, just buy some of that and lop sections off, will be continously threaded mind, so that might not get a bite into the carb so you can tighten nylocks onto it

If you are still playing with that one, the way I found easiest was to drill out the carb top 5.5mm, and the air filter 6mm, and re tap the carb top, then use normal bolts. If I knew at the time, I think I would have made up some studs though.

B&Q sell 6mm threaded rod by the metre, just buy some of that and lop sections off, will be continously threaded mind, so that might not get a bite into the carb so you can tighten nylocks onto it

'89(G) 340 GLE B172k

'03 S60 D5 SE, '91 (J) MX5, 1954 Cyclemaster

Ex:

'89(F) 340 GL F7R (ex B172k) - Fake -> SBKV 300 Runner Up 08, 12; '91(H) 340 GL B14.4E - Kar; '88(F) 360 GLT B200E - Jet -> BKV 300 Runner Up 09; '89(G) 360 GLT B200E - Beast

'03 S60 D5 SE, '91 (J) MX5, 1954 Cyclemaster

Ex:

'89(F) 340 GL F7R (ex B172k) - Fake -> SBKV 300 Runner Up 08, 12; '91(H) 340 GL B14.4E - Kar; '88(F) 360 GLT B200E - Jet -> BKV 300 Runner Up 09; '89(G) 360 GLT B200E - Beast

Naughty, naughty - threaded rod through plastic housing - hole soon get bigger!!.

Seriously, the housing also relies on the studs for horizontal positioning - not just the clamping force of the nuts. If you rely only on the nuts you risk over tightening and pulling the threads out again!! It doesn't take much movement for a steel thread to grind away at plastic.

(sorry if it seems like criticism Chris)

Mac.

Seriously, the housing also relies on the studs for horizontal positioning - not just the clamping force of the nuts. If you rely only on the nuts you risk over tightening and pulling the threads out again!! It doesn't take much movement for a steel thread to grind away at plastic.

(sorry if it seems like criticism Chris)

Mac.

Don't worry about it mate, I'm more than happy to be corrected! Means I won't make a t*t of myself when I do it to my cars

'89(G) 340 GLE B172k

'03 S60 D5 SE, '91 (J) MX5, 1954 Cyclemaster

Ex:

'89(F) 340 GL F7R (ex B172k) - Fake -> SBKV 300 Runner Up 08, 12; '91(H) 340 GL B14.4E - Kar; '88(F) 360 GLT B200E - Jet -> BKV 300 Runner Up 09; '89(G) 360 GLT B200E - Beast

'03 S60 D5 SE, '91 (J) MX5, 1954 Cyclemaster

Ex:

'89(F) 340 GL F7R (ex B172k) - Fake -> SBKV 300 Runner Up 08, 12; '91(H) 340 GL B14.4E - Kar; '88(F) 360 GLT B200E - Jet -> BKV 300 Runner Up 09; '89(G) 360 GLT B200E - Beast