Page 1 of 2

pilot bearing install on B200

Posted: 13 Jul 2006 08:33 pm

by volvo300

Hi.

I'm about to change the clutch on my 360 GLT.

My approach is to take the engine out of the car.

My question is:

- Haynes writes, that the pilot bearing must be installed "packed with grease". WHY? I have bought a new pilot bearing (and circlip) and it's a closed / sealed bearing!

Am I missing something here? How do you guys install a pilot bearing on a B200? With or without grease? If "with grease" then which type?

Thanks in advance

Regards.

Peter

Posted: 13 Jul 2006 09:33 pm

by pettaw

Nah, its fine, just smear it with grease and stick it in and then put the circlip on top of it. Sometimes the Haynes can be a bit funny

Posted: 14 Jul 2006 09:37 am

by mac

Pettaw's quite right - just a little lube on the end of the shaft and around the bearing and in it goes. It should be 'sealed for life'.

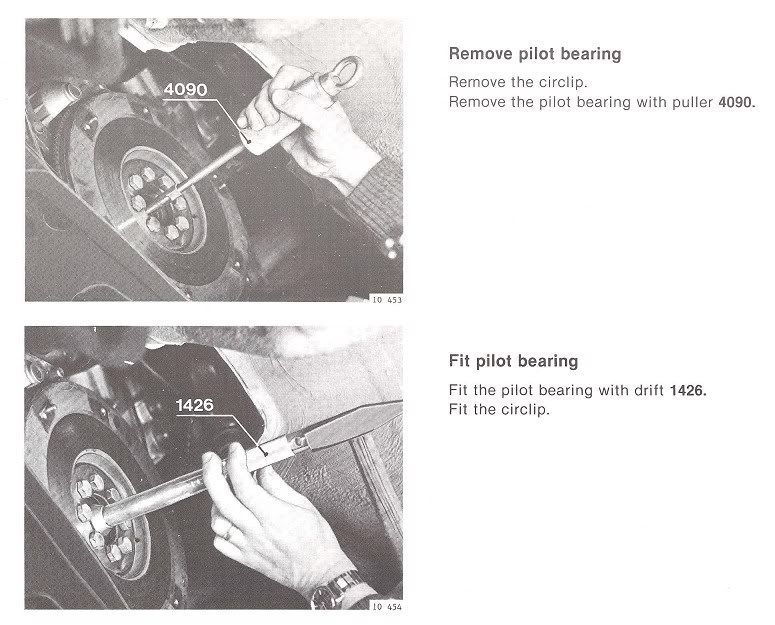

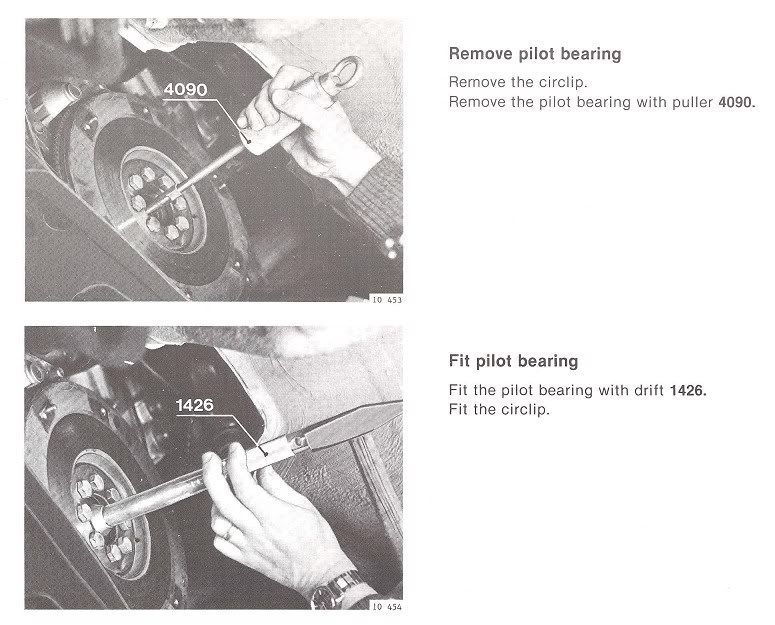

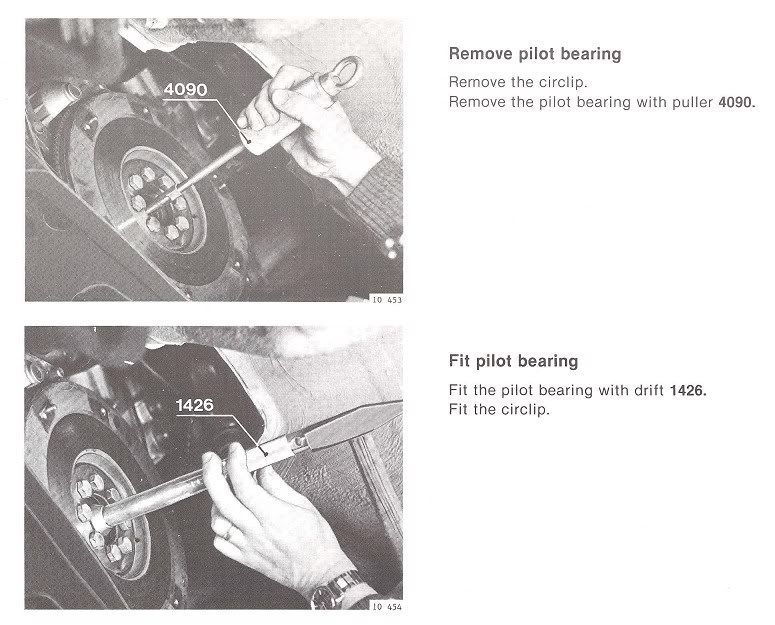

Here is all the factory manual says - no mention of grease at all.

I think one problem of Haynes is that they tend to updated previous versions of the manual in only the obvious areas. Originally the 300 only had the B14 of course, and upto ch.no.385680 the pilot bearing was a cased needle roller that needed packing with grease on installation. After this the bearing was changed to a sealed ball race (clutch shaft also changed). The 360 always has had a sealed bearing but I guess 'Haynes' just carried over the 'old' description in the updated manual!!

Mac.

Posted: 14 Jul 2006 10:59 pm

by volvo300

Thanks guys

That helps a lot.

That's some nice pics mac.

I'll just tap the bearing in there. What do you guys use to drift it in? Do you use the old bearing or what? I don't wanna destroy the bearing when I drift it in! In the old days I used a socket, but is that good enough?

I'll post some pics of the job in the near future.

Regards.

Peter

Posted: 16 Jul 2006 10:30 pm

by arnagath

mac wrote:

Do you have this kind of pictures from propshaft fitting? Im more than happy if you have it

Posted: 17 Jul 2006 02:53 pm

by mac

Hi there arnagath,

I can almost certainly find something to help, but to save posting what you don't need can you confirm the model (B14, B17, B19/200) and what you are actually doing ie, Clutch change, propshaft only change, etc. etc.

Best regards - Mac.

Posted: 17 Jul 2006 09:34 pm

by arnagath

Hi mac

Im changing propshaft, replacing broken one to new propshaft and I`d like to do that properly..Engine is b200e.

Ive changed b172 engine to b200e and ive got it almost finished but now propshaft makes rattling-noises. I do know why..

One part my own stupidness, one part tired

Posted: 18 Jul 2006 12:26 pm

by mac

Hi again arnagath, sorry to come back with more questions, but you say you have converted to a B200 from a B172 so I assume you have the 360 transmission and torque tube already installed ?? but have a problem with the drive quill (inside the tube), or the quill bearings, or the connector at the rear that links the drive quill to the g/box input shaft.

Is the faulty propshaft still installed?, or are you ready to simply fit the replacement?. Are you intending to replace the whole torque tube, or just the drive quill, or the connector only. You say you know what the problem is - please describe it (common problem is forgetting to correctly tighten the connector clamps!).

Knowing exactly what your problem is will hopefully help me describe the easiest repair.

All the best - Mac.

Posted: 18 Jul 2006 10:13 pm

by arnagath

mac wrote:Hi again arnagath, sorry to come back with more questions, but you say you have converted to a B200 from a B172 so I assume you have the 360 transmission and torque tube already installed ?? but have a problem with the drive quill (inside the tube), or the quill bearings, or the connector at the rear that links the drive quill to the g/box input shaft.

Is the faulty propshaft still installed?, or are you ready to simply fit the replacement?. Are you intending to replace the whole torque tube, or just the drive quill, or the connector only. You say you know what the problem is - please describe it (common problem is forgetting to correctly tighten the connector clamps!).

Knowing exactly what your problem is will hopefully help me describe the easiest repair.

All the best - Mac.

Yes i have 360 transmission and torquetube already installed. I havent got off broken propshaft, i havent got any motivation for that job

Im replacing whole propshaft/torquetube..

Problem is like this..Since i was removing transmission from 360 GLT me and my workmate tryied to remove torquetube from transmission we hitted with hammer to propshaft inside torquetube

And that is the reason why i have to replace it..Quill bearings got somekind of hit and those are smashed for now. I have bought "new" torquetube/propshaft. Connector clamps are tightened properly to right Nm..

Ill try to describe this problem:

Starting car, clutch down and 1st gear in, clutch up *KLONKS*, car moves,speeding, clutch down 2nd gear in, clutch up *KLONKS*, speed about 40km/h and 3000-4000rpm and then starts huge shaking from back of and huge rattling sound and feels like car is breaking to my hands

...This same thing continues EVEN i have lifted rearend up and changing gear etc. So problem MUST be broken quill bearings.

Sorry for bad english, try to understand something

Posted: 19 Jul 2006 12:13 pm

by mac

Ok arnagath, here we go - bit of a marathon I'm afraid !!

There are two ways to approach this job but I will describe the method as for a clutch change - this will cover everything apart from the disconnection of the driveshafts from the differential which would also be needed if you wished to remove the whole transmission.

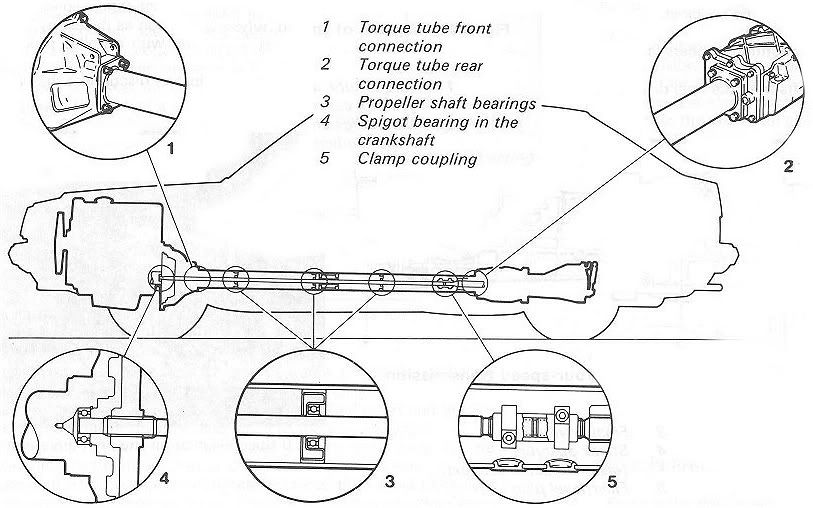

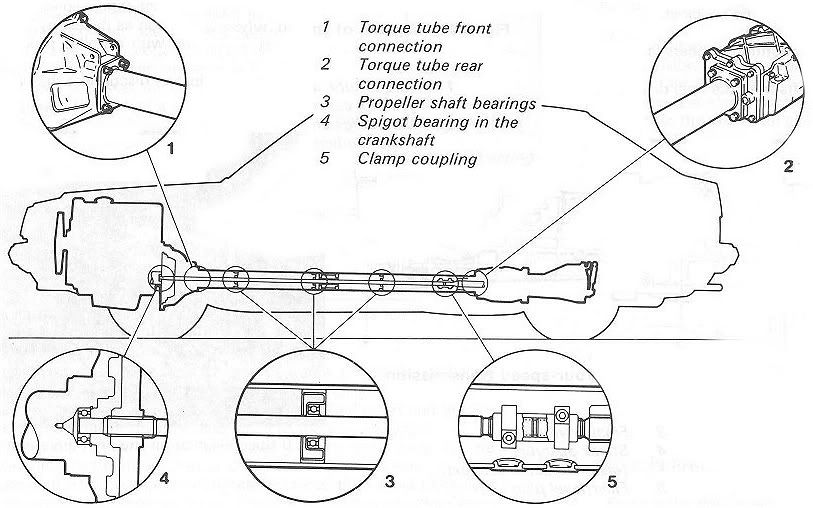

As you know the 360 transmission is linked to the engine by a rigid torque tube which carries the drive through a drive quill supported in two bearings.

The front end of the quill is carried in the flywheel pilot bearing and is splined to the clutch centre plate. The rearof the quill is also splined and is connected to the gearbox input shaft by a short splined tube fitted with two clamps (within the torque tube). Access is gained by removing two grommets on the underside of the torque tube just in front of the gearbox.

Proceedure as follows:- Click the pix to enlarge.

Disconnect battery,

Remove the bracket from the clutch bell housing to the exhaust downpipe,

Remove the remaining top bolt from the bellhousing and the top bolt from the starter motor,

Raise the car front and rear on stands (or a wheel free ramp if you have access). The rear wheels must 'hang',

Remove the engine splash guards and the flywheel guard from the lower front section of the bell housing,

Disconnect the clutch cable,

Remove the exhaust system, diconnecting at joint C. Disconnect the exhaust downpipe from the manifold and remove the bracket from the bottom two nuts of the torque tube front plate,

Release the handbrake cables from the clips on the fuel tanks,

Remove the remaining bell housing bolts and the remaining starter motor bolt,

Remove the gear linkage stabiliser rod from the rear of the bell housing (remove the clip and push the pivot pin to the left,

Release the gear linkage mount fron the top of the torqur tube,

Will continue shortly.

Posted: 19 Jul 2006 12:38 pm

by mac

Part two!

Remove the fuel tank heat shield,

Detach the gear selector rod from the gearbox, (slide back the locking sleeve and remove the pin),

Support the transaxle on a trolley jack or sliding jacking beam,

Remove the two transaxle mounting bolts,

Slide the entire drive line to the rear (over the axle - taking care not to damage the brake pipe running along the axle beam) until the drive quill is clear of the clutch unit. Allow the bell housing/torque tube to swing downwards at the front.

Note:- On some vehicles it may be necessary to release the rear spring hangers to allow the axle to drop sufficiently to enable to transaxle unit to pass above the axle beam.

Remove the clutch release fork and bearing from the bellhousing,

Remove the two remaining (top) nuts securing the bell housing to the torque tube and pull the bell housing away,

Ensure the transaxle is still securely supported,

Remove the two securing bolts from the connector sleeve in the rear of the torque tube (remove the bolts completely - the act as cotter pins),

Remove the four bolts that secure the rear of the torque tube to the gearbox,

To be continued.

Posted: 19 Jul 2006 01:07 pm

by mac

Part three!

Now all fixings have been removed the old torque tube assembly can be withdrawn.

Refitting the new unit is a reversal of the removal proceedure.

After installation the clutch cable must be adjusted,

Measurement A (between the top surface of the clutch pedal pad and the floor carpet) should be adjusted to 150mm +/- 5mm (for LHD card). The adjustment is made at the release fork end of the clutch cable.

Torque settings:-

Bell housing bolts 60Nm

Torque tube nuts 42Nm (tube to bellhousing)

Torque tube bolts 42Nm (tube to gearbox)

Transaxle mounts 47Nm

Drive quill connector 34Nm (do NOT lubricate splines).

I hope the above posts will help you - your problem does sound very much llike a collapsed quill bearing (very rare!) - but it is just possible the problem lies with the gearbox mainshaft or one of the driveshaft CV joints.

Do let us know how you get on and what the problem turns out to be.

All the best - Mac.

Posted: 19 Jul 2006 01:44 pm

by jtbo

If problem is coming with speed, not with rpm then problem should not be in torque tube, but transmission/differential/driveshafts.

Posted: 19 Jul 2006 02:40 pm

by mac

Hi jtbo,

I must admit my first thought was a broken up CV joint on one of the driveshafts or a failed stub shaft bearing in the diff - and if the problem is only there 'on the road' it cannot be drive quill or gearbox input shaft. (which would give the problem stationary in neutral gear).

However arnagath seems confident that he damaged a drive quill bearing and it is (in his words) 'smashed'. He thinks a change of torque tube will cure the problem - and I'm happy to post the info he wants. I did try to get more to the root of the failure but I'm still not sure either of us fully understand each other!! I still wonder if it will turn out to be a bigger problem than he thinks!

I guess we'll hear soon enough,

Mac.

Posted: 19 Jul 2006 06:40 pm

by arnagath

Thank you mac very much. I really appreciate this info with a lot of pics

I really hope that this problem figures out with only changing propshaft..I will keep you in touch with this subject. I will do this operation within a month.

Jtbo,problem is coming with rpm but not when gear is in neutral

Or have i just putted propshaft already wrong?!?