Gearbox info please

Gearbox info please

Hi,

New member here, havent quite got the hang of things,considering transplanting a 340 engine/transaxle into an old triumph kit car but need to know a couple of dimensions for the gearbox to see if it will fit behind the seats.If anyone has a five speed out of the the car would you mind measuring the distance between the front of the gearbox (not including the prop shaft extension tube) and the output shafts centre.Width and height would also be useful.Are cv joints the same inner/outer and are 360 joints and shafts the same fitting as 340.Macs superb submissions/photos inspired me to consider this.

Thanks in anticipation

oldgit

New member here, havent quite got the hang of things,considering transplanting a 340 engine/transaxle into an old triumph kit car but need to know a couple of dimensions for the gearbox to see if it will fit behind the seats.If anyone has a five speed out of the the car would you mind measuring the distance between the front of the gearbox (not including the prop shaft extension tube) and the output shafts centre.Width and height would also be useful.Are cv joints the same inner/outer and are 360 joints and shafts the same fitting as 340.Macs superb submissions/photos inspired me to consider this.

Thanks in anticipation

oldgit

-

petefarrell360

- *** V3M DONOR ***

- Posts: 3083

- Joined: 11 Oct 2004 07:12 pm

- Location: Bucks, UK

Talk to Andy aka Pettaw nicely, he should have a 5 speed box lying around that he might be able to measure.

AFAIK the drive shafts are the same size both ends. They are swappable between the 340 and 360, however the 360 GLT ones for sure are thicker on the shaft and use hex headed bolts, rather than an allen key fitting.

Sounds like an interesting project.

Pete

AFAIK the drive shafts are the same size both ends. They are swappable between the 340 and 360, however the 360 GLT ones for sure are thicker on the shaft and use hex headed bolts, rather than an allen key fitting.

Sounds like an interesting project.

Pete

G reg 360 GLT, G reg 340 GL Variomatic, plus many more..........

Evnin,

First point - whilst dimensionally the same the transaxles of a 340 and a 360 mount in entirely different ways. I assume you know but 1.4 or 1.7 = 340 and 2.0 = 360. 340 has aluminium propshaft with rubber bushes containing a splined fitting at each end and a 360 has an enclosed quill shaft drive in a torque tube. 340 transaxle mounts to two beams mounted to the body whereas a 360 transaxle has rear mounts only (different to 340) the front mounting being the engine (support carried by torque tube). In either case it is not a simple job to change the length of the propshaft or torque tube.

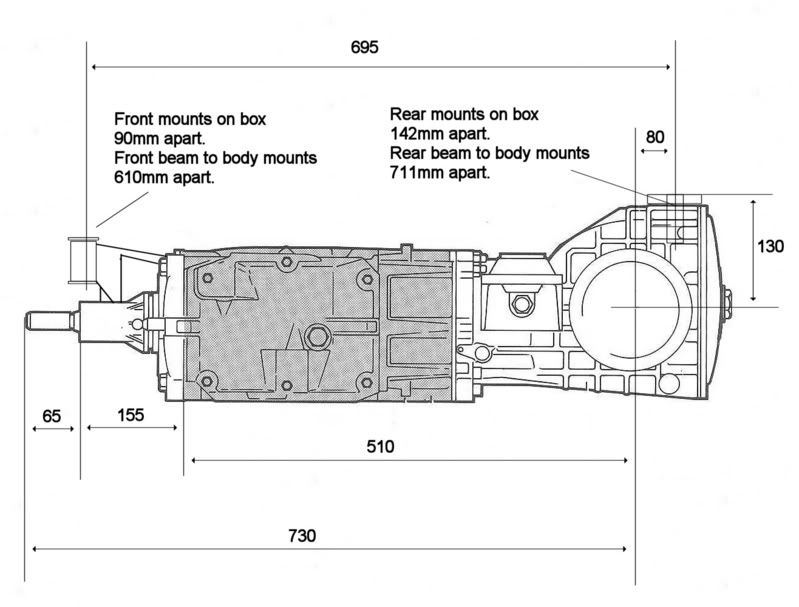

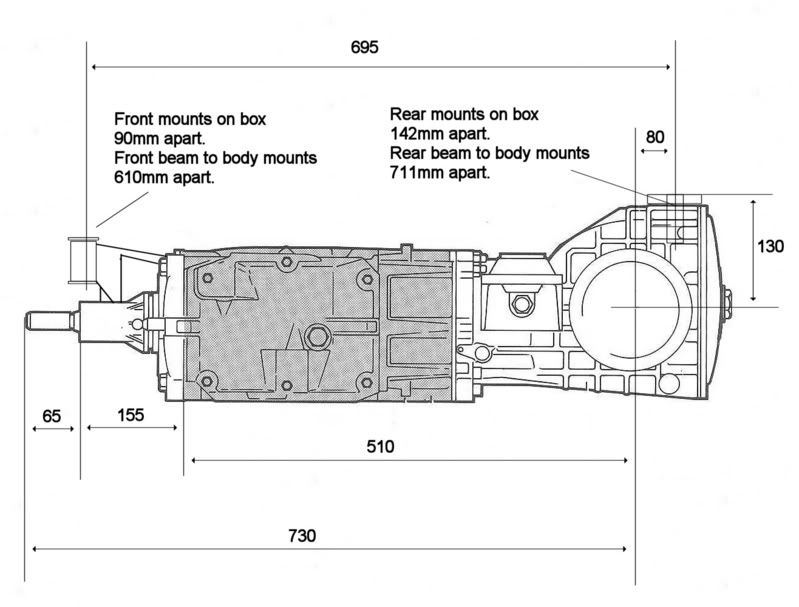

Dimensions for 340 M47R below (1.4 or 1.7).

hopes this helps - if you need more just shout.

Mac.

First point - whilst dimensionally the same the transaxles of a 340 and a 360 mount in entirely different ways. I assume you know but 1.4 or 1.7 = 340 and 2.0 = 360. 340 has aluminium propshaft with rubber bushes containing a splined fitting at each end and a 360 has an enclosed quill shaft drive in a torque tube. 340 transaxle mounts to two beams mounted to the body whereas a 360 transaxle has rear mounts only (different to 340) the front mounting being the engine (support carried by torque tube). In either case it is not a simple job to change the length of the propshaft or torque tube.

Dimensions for 340 M47R below (1.4 or 1.7).

hopes this helps - if you need more just shout.

Mac.

Thanks again for the diagram mac,it looks as if I might be able to squeeze it in,(its a two+2 at the moment !) Any spare 5 speed gearboxes currently available ? it can be a duff one for mock up purposes.A couple of inner cv joints (again could be duff )also required . I have seen mention of steel propshafts is there a company that specialises in these?

Thanks all for your help

oldgit

Thanks all for your help

oldgit

Mornin' all,

Just a quick comment about propshafts - I'm sure you have realised this already 'oldgit' but remember when deciding on how to connect your engine to the transaxle that gear selection takes place in the transaxle so your propshaft (of whatever form) will always be turning at engine speed - even in neutral with car stationary. You will need to keep the rotating mass as low as possible and get the balance as near as perfect as you can.

(hence the 340 using an alloy tube and the 360 a drive quill)

All thing considered it might be advisable to go for a 360 transaxle and shorten the torque tube arrangement (the tube itself would be easy enough to 'chop' and the drive quill could either be cut, shortened and splined or shortened and new splines machined or broached). It would also be a more satisfactory solution 'engineering' wise! The front of the torque tube is a simple flat plate mounting to the bell housing and should be easy to adapt.

What engine are you using BTW and what is the 'kit' it's all going in ??

The other obvious question is what rear end are you using (you say a Triumph kit) - Herald/Vitesse ??. If so I assume you intend to adapt the 300 inner CV joints to the Triumph shafts - watch out for shaft length giving

articulation problems if you need to shorten them much (I doubt the Triumph diff is much narrower than the 300 one anyway).

If you are using a Triumph rear end you will probably need to make up a combined transaxle/transverse spring mount to keep the drive shafts in line and this may bring the diff. a little low (I think the 300 unit will be rather deeper than a Herald diff.).

Sorry if I'm rambling a bit - I'm just saying things as they come to mind !!

As for mock up parts - I'm sure someone on v3m will have a line on some bits for you.

All the best - Mac (a genuine 'old git')

Just a quick comment about propshafts - I'm sure you have realised this already 'oldgit' but remember when deciding on how to connect your engine to the transaxle that gear selection takes place in the transaxle so your propshaft (of whatever form) will always be turning at engine speed - even in neutral with car stationary. You will need to keep the rotating mass as low as possible and get the balance as near as perfect as you can.

(hence the 340 using an alloy tube and the 360 a drive quill)

All thing considered it might be advisable to go for a 360 transaxle and shorten the torque tube arrangement (the tube itself would be easy enough to 'chop' and the drive quill could either be cut, shortened and splined or shortened and new splines machined or broached). It would also be a more satisfactory solution 'engineering' wise! The front of the torque tube is a simple flat plate mounting to the bell housing and should be easy to adapt.

What engine are you using BTW and what is the 'kit' it's all going in ??

The other obvious question is what rear end are you using (you say a Triumph kit) - Herald/Vitesse ??. If so I assume you intend to adapt the 300 inner CV joints to the Triumph shafts - watch out for shaft length giving

articulation problems if you need to shorten them much (I doubt the Triumph diff is much narrower than the 300 one anyway).

If you are using a Triumph rear end you will probably need to make up a combined transaxle/transverse spring mount to keep the drive shafts in line and this may bring the diff. a little low (I think the 300 unit will be rather deeper than a Herald diff.).

Sorry if I'm rambling a bit - I'm just saying things as they come to mind !!

As for mock up parts - I'm sure someone on v3m will have a line on some bits for you.

All the best - Mac (a genuine 'old git')

Thanks for the comprehensive and considered reply mac, dont have much time this weekend (daughter bringing boyfriend home for the first time any minute now ?!) will post again later . Its a spartan +2, box section chassis,hoping to junk the swing axle suspension at the rear.

Thanks

oldgit (we're both genuine old gits then)

Thanks

oldgit (we're both genuine old gits then)

-

petefarrell360

- *** V3M DONOR ***

- Posts: 3083

- Joined: 11 Oct 2004 07:12 pm

- Location: Bucks, UK

I might be able to help with the gearbox if you're really stuck at any point. Andy/Pettaw has his old gearbox that wasn't too healthy, he may be glad of someone to make use of it, or he may wish to open it up to investigate, either way, when he's back, might be worth asking him.

Pete

Pete

G reg 360 GLT, G reg 340 GL Variomatic, plus many more..........

Whoa, that's a weird one - if you need to lay down some groundrules you might find This usefuloldgit485 wrote:daughter bringing boyfriend home for the first time any minute now ?!

Ronnie, very funny/useful advice thanks.

mac, I have been haunted by thoughts of a propshaft flailing around at engine speed under a wafer thin aluminium transmission tunnel ! Thanks for the 360 info I think I will go and lie under one for an hour or two and get some inspiration.I have visions of getting rid of the transverse spring and the swing axles.I had imagined that I could probably buy an MOT failure for less than the cost of a reconditioned triumph diff and end up with a more modern engine and five speed transmission to boot.It does seem though that you are facing parts supply problems with the volvo 300 series but you all seem to be resourceful enough to keep them on the road for many years yet.I dont seem to see the CV joints listed at eurospares/german & swedish,are they still available?

Thanks for all your help,I will return after due examination.

oldgit

mac, I have been haunted by thoughts of a propshaft flailing around at engine speed under a wafer thin aluminium transmission tunnel ! Thanks for the 360 info I think I will go and lie under one for an hour or two and get some inspiration.I have visions of getting rid of the transverse spring and the swing axles.I had imagined that I could probably buy an MOT failure for less than the cost of a reconditioned triumph diff and end up with a more modern engine and five speed transmission to boot.It does seem though that you are facing parts supply problems with the volvo 300 series but you all seem to be resourceful enough to keep them on the road for many years yet.I dont seem to see the CV joints listed at eurospares/german & swedish,are they still available?

Thanks for all your help,I will return after due examination.

oldgit